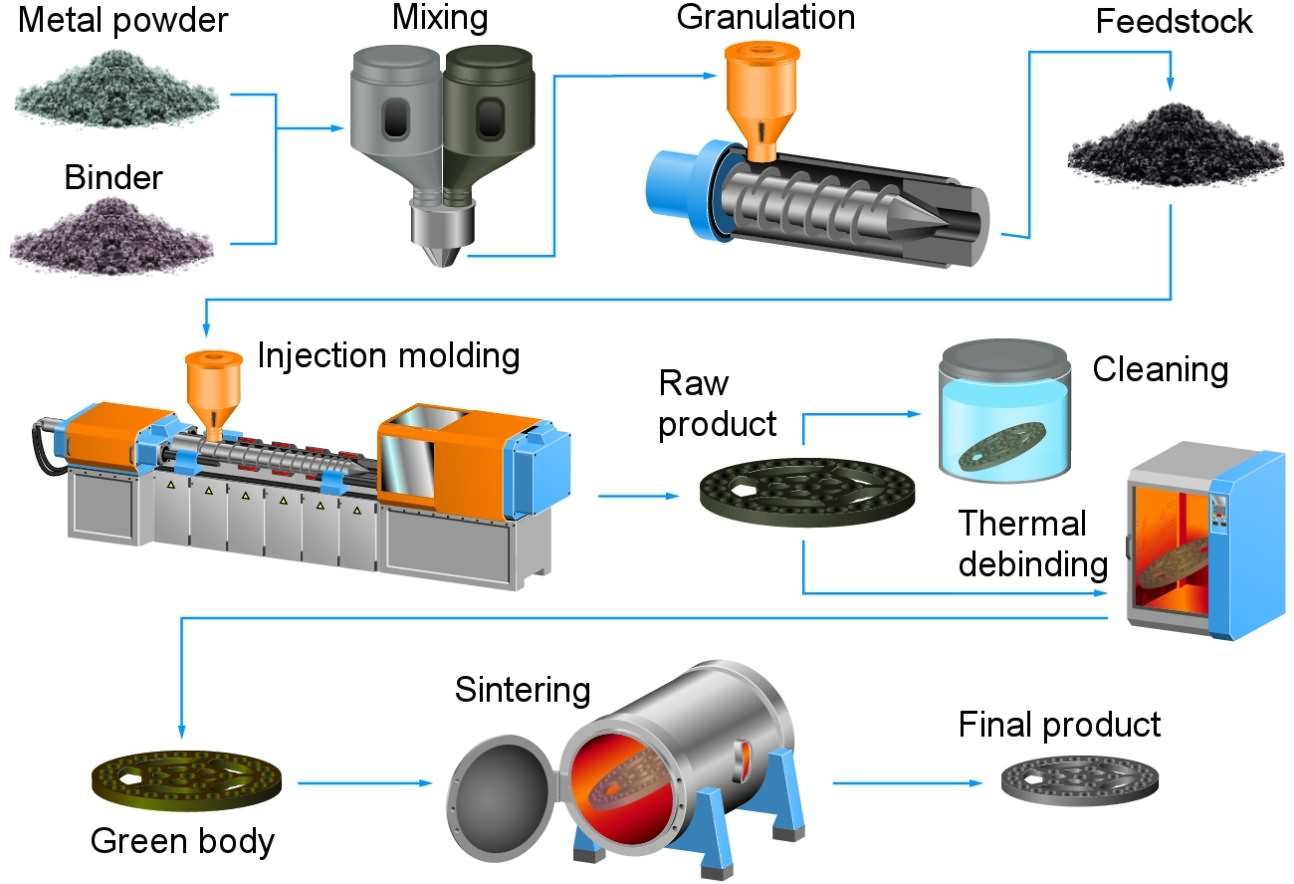

I-MIM i-Metal Injection Molding, inqubo yokusebenza kwensimbi lapho insimbi ewumpushana ocolisekile ixutshwa nezinto ezihlanganisayo ukuze kwakhiwe “i-feedstock” ebese ibunjwa futhi iqiniswe kusetshenziswa ukubumba komjovo.Inqubo yokubumba ivumela ivolumu ephezulu, izingxenye eziyinkimbinkimbi ukuba zibunjwe ngesinyathelo esisodwa.Ngemuva kokubumba, ingxenye ingena emisebenzini yokulungisa ukuze isuse i-binder (debinding) futhi igxilise ama-powders.Imikhiqizo eqediwe yizici ezincane ezisetshenziswa ezimbonini eziningi nasekusetshenzisweni.

Ngenxa yemikhawulo yemishini yamanje, imikhiqizo kufanele ibunjwe kusetshenziswa inani lamagremu ayi-100 noma ngaphansi "kukudubula" ngakunye.Lesi sithombe singasatshalaliswa emigodini eminingi, okwenza i-MIM ingabizi kakhulu emikhiqizweni emincane, eyinkimbinkimbi, enevolumu ephezulu, ebingabiza ukuyikhiqiza.I-MIM feedstock ingakhiwa inqwaba yezinsimbi, okokuqala into ejwayeleke kakhulu izinsimbi ezingenasici ezisetshenziswa kakhulu ekwenzeni impushana yensimbi, kodwa manje amabhizinisi ambalwa asebenzisa ubuchwepheshe bokukhiqiza obuvuthiwe bokusebenzisa i-Brass ne-Tungsten alloy njengento ephathekayo, futhi enze i-MIM. imikhiqizo inokusebenza okwengeziwe futhi isetshenziswa kabanzi ezimbonini ezahlukahlukene.I-KELU iyona enekhono lokusebenzisa i-Brass, i-Tungsten ne-Stainless Steels njengezinto ze-MIM zokukhiqiza ngobuningi.Ngemuva kokubunjwa kokuqala, i-feedstock binder iyasuswa, futhi izinhlayiya zensimbi ziyahlanganiswa futhi zihlanganiswe ukuze kuzuzwe izakhiwo zamandla ezifunwayo.

Izinzuzo ze-MIM wukubona izingxenye ezincane ezisebenza kahle kakhulu ekukhiqizeni ngobuningi, nokuba nokubekezelelana okuqinile nokuba yinkimbinkimbi ngesikhathi esifanayo.Emikhiqizweni yokugcina, singasebenzisa izindlela zokwelapha ezihlukene ukuze sithole umphumela ohlukile ukuze sihambisane nezidingo ezahlukene.

Isikhathi sokuthumela: Apr-24-2020