Well-designedCustom Service- Jewelry Accessory – kelushare

Well-designedCustom Service- Jewelry Accessory – kelushare

Well-designedCustom Service- Jewelry Accessory – kelushare Detail:

MIM (Metal Injection Molding), the hottest technology for 21st century should be the best solution for Jewelry Industrial because of its small size, complicated constructure, tight tolerance, high fineness on the surface and mass production requirement.

Tiny accessory may not be realized by other technologies, but MIM Material utilization can be up to 95% and above. And not only realized the small tiny parts, but also with productivity and lower labor cost.

MIM PROCESSES

The CORE TECHNOLOGIES KELU has are MIM and CNC, both for the high-end sport components.

Metal injection molding (MIM) is a revolutionary technology which integrating Plastic Injection Molding, Polymer chemistry, Powder metallurgy and Metallic materials science. We can develop mold for special customized size/shape or produce by existing mold directly. Tungsten, Brass, Stainless Steel could be chosen as materials for MIM.

Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. And its applicative materials include Titanium, Tungsten, Aluminum, Brass, Stainless Steel, Zinc and so on.

Main Markets:

North Americam, Europe, Australia, Asia

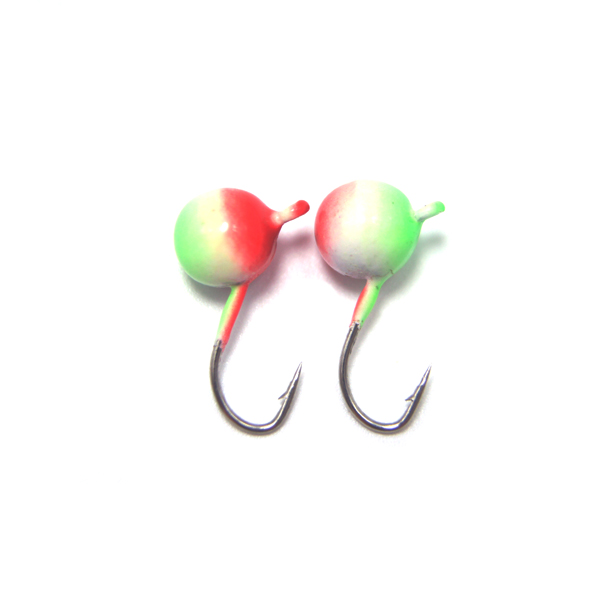

Product detail pictures:

Related Product Guide:

We attempt for excellence, provider the customers, hopes to be the most beneficial cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes value share and continuous advertising for Well-designedCustom Service- Jewelry Accessory – kelushare , The product will supply to all over the world, such as: Brazil, Palestine, Algeria, Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact me. We are looking forward to forming successful business relationship with new clients around the world.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.