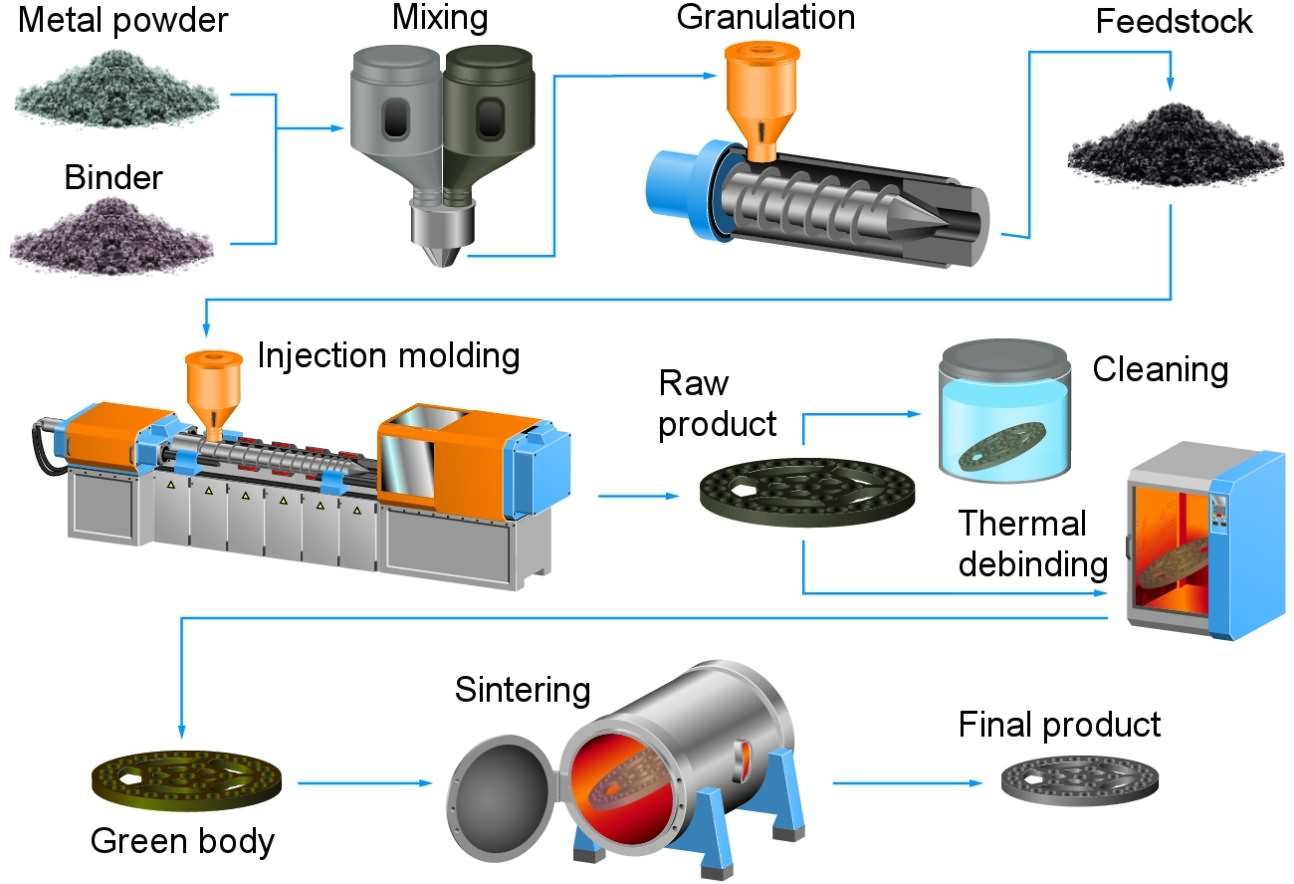

MIM is Metal Injection Molding, isimbi yekugadzira iyo simbi yakatsetseka-upfu inosanganiswa nebinder material kugadzira “feedstock” inozoumbwa nekusimbaradzwa uchishandisa jekiseni.Maitiro ekuumba anobvumira yakakwira vhoriyamu, yakaoma zvikamu kuumbwa mune imwe nhanho.Mushure mekuumbwa, chikamu chinopinda maitiro ekugadzirisa kubvisa binder (debinding) uye densify hupfu.Zvigadzirwa zvakapedzwa zvikamu zvidiki zvinoshandiswa mumaindasitiri mazhinji uye maapplication.

Nekuda kwekushomeka kwemidziyo iripo, zvigadzirwa zvinofanirwa kuumbwa uchishandisa huwandu hwe100 gramu kana zvishoma pa "pfuti" muforoma.Iyi pfuti inogona kugoverwa mumakomba akawanda, zvichiita kuti MIM idhure kune zvidiki, zvakaoma kunzwisisa, zvigadzirwa zvemhando yepamusoro, izvo zvingave zvichidhura kugadzira.MIM feedstock inogona kuumbwa nekuwanda kwesimbi, chekutanga zvinhu zvakajairika isimbi isina tsvina iyo inoshandiswa zvakanyanya muupfu simbi, asi iko zvino mabhizinesi mashoma ano hunyanzvi hwekugadzira tekinoroji yekushandisa Brass neTungsten alloy sechinhu, uye kugadzira iyo MIM. zvigadzirwa zvine kuita kwakawanda uye kushandiswa kwakakura mumaindasitiri akasiyana.KELU ndiye anokwanisa kushandisa Brass, Tungsten uye Stainless Steels seMIM zvinhu zvekugadzira hukuru.Mushure mekutanga kuumbwa, iyo feedstock binder inobviswa, uye zvimedu zvesimbi zvinosanganiswa zvakasungwa uye densified kuti zvizadzise zvinodiwa simba zvivakwa.

Zvakanakira zveMIM kuona zvikamu zvidiki zvine hunyanzvi mukugadzirwa kwakawanda, uye kuve nekushivirira kwakasimba uye kuomarara panguva imwe chete.Pazvigadzirwa zvekupedzisira, tinogona kushandisa marapirwo akasiyana epamusoro kuti tiwane maitiro akasiyana epamusoro kuti aenderane nezvinodiwa zvakasiyana.

Nguva yekutumira: Kubvumbi-24-2020